The LED industry has entered a mature and saturated phase, prompting manufacturers to adjust their development strategies and expand into niche markets such as automotive lighting, plant lighting, UV LED, IR LED, as well as new display fields like small pitch, Mini/Micro LED. Among these, in the UV LED sector, although many manufacturers have been involved for some time, the acceptance of UV LED products in the market has been relatively low in the past. Consequently, the UV LED industry has been in its infancy, especially for UVC LEDs, which pose higher technical difficulties and prices.

However, since the global spread of the novel coronavirus pneumonia epidemic, consumer awareness of sterilization and disinfection has rapidly increased. The epidemic prevention opportunities have driven a surge in demand for UVC LED products, prompting global efforts to develop UVC LED technology and giving rise to a variety of products. However, are all these products meeting the relevant requirements?

In fact, there are many factors to consider when selecting reliable UVC LED products. For instance, different viruses and bacteria require different doses and irradiation times to achieve disinfection and sterilization effects. Moreover, in the production process, there are many factors to consider, from epitaxial chips to packaging and finished products. In this context, Yingfeng Technology has revealed the materials, processes, technical challenges, and development trends required for UVC LED packaging to better understand UVC LED packaging products.

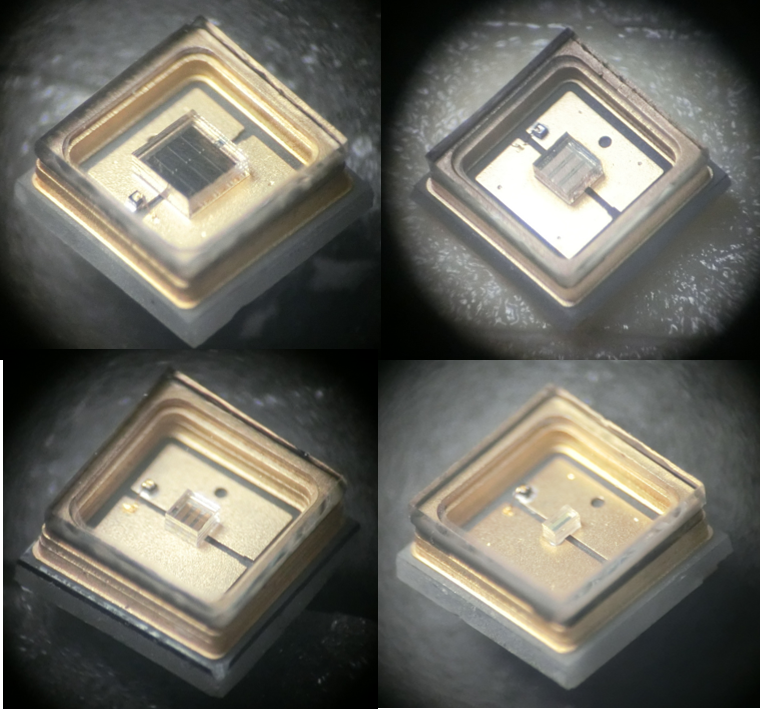

Specifically, there are three forms of UVC LED packaging: organic packaging, semi-inorganic packaging (also known as “near-inorganic packaging”), and full inorganic packaging.

Organic packaging uses organic materials such as silicone gel, silicone resin, or epoxy resin. This includes products like lamps, SMDs, and ceramic moldings. While the overall technology is relatively mature, the resistance to UV radiation still needs to be improved.

Semi-inorganic packaging utilizes organic silicon materials combined with inorganic materials such as glass. Full inorganic packaging avoids the use of organic materials entirely, achieving the lens and substrate combination through methods like laser welding, wave soldering, or resistance welding. This completely eliminates issues related to organic material-induced light attenuation and failures caused by thermal stress, effectively enhancing the stability and reliability of UVC LED devices.

Currently, semi-inorganic packaging products remain the mainstream in the domestic market, primarily consisting of ceramic support brackets and quartz glass. The placement of the lens is achieved by applying UV-resistant adhesive to the edge area of the ceramic substrate cup and then curing it by covering it with quartz glass.

In terms of material selection, UVC LED packaging differs from general LED packaging. Firstly, quartz glass is chosen because it is inorganic, unaffected by UV light, and has high transmittance in the UVC wavelength range. Secondly, for heat dissipation substrates, high thermal conductivity aluminum nitride substrates are commonly used due to the low optical-electrical conversion efficiency of UVC LEDs, with most of the energy converting into heat. Additionally, since UVC is detrimental to adhesives, the requirements for the UV resistance of the adhesive bonding glass and bracket are higher compared to general LED packaging.

It is worth noting that some manufacturers use aluminum oxide heat dissipation substrates. Both aluminum nitride and aluminum oxide substrates are ceramic substrates, but the main difference lies in their thermal conductivity. The thermal conductivity of aluminum nitride is generally around 140W/mK-170W/mK, while that of aluminum oxide is only around 30W/mK.

Alumina ceramics are usually white and have low thermal conductivity, typically used for low-power products. However, alumina ceramics are more brittle and prone to fracture compared to aluminum nitride, especially during the dicing process, where chipping is common. Aluminum nitride ceramics are generally gray-black, with high thermal conductivity, typically used for high-power products. Additionally, there are alumina ceramics doped with carbon powder available in the market, which also appear gray-black but have lower thermal conductivity.

Heat management and air tightness affect the quality of UVC LED packaging products, and both are technical challenges in the packaging process. Heat management directly affects the lifespan of UVC LED packaging products, while air tightness largely determines their reliability.

UVC LEDs are heat-sensitive, with low external quantum efficiency (EQE), meaning only a small portion of electrical energy is converted into light, while the majority is converted into heat, directly affecting the chip’s lifespan. Given this, many products currently utilize flip-chip technology combined with high thermal conductivity aluminum nitride substrates. Aluminum nitride boasts excellent thermal conductivity, able to withstand the aging of UV light sources and meet the high heat management requirements of UVC LEDs.

Apart from materials, packaging processes also play a role in heat management. Packaging processes mainly focus on die bonding technology, including silver paste soldering, solder paste soldering, and gold-tin eutectic soldering.

While silver paste soldering has good adhesion, it is prone to silver migration, leading to device failure. As for solder paste soldering, its melting point is only around 220 degrees Celsius, so after the device is mounted, reflow soldering may cause re-melting, leading to chip detachment and failure, affecting the reliability of UVC LEDs.

Gold-tin eutectic soldering mainly relies on eutectic soldering through soldering flux, effectively enhancing the bonding strength and thermal conductivity between the chip and the substrate, resulting in higher reliability and better quality control of UVC LED products. Therefore, gold-tin eutectic soldering is widely used in the market.

In soldering processes, the issue of voids is particularly significant. Solder voids refer to defects formed during the bonding process of LED chips and substrates, presenting as voids in appearance. It is an important indicator affecting heat dissipation: the lower the void rate, the better the heat dissipation effect, the longer the product lifespan, and the better the quality.

It is understood that Yingfeng ‘s inorganic packaging technology utilizes a mixture of inert gases and reducing gases to protect the chips under a hot pressing eutectic soldering process, further increasing electrical connection efficiency, reducing void rates, and stabilizing LED junction temperatures.

Yingfeng ‘s advantages and characteristics in eutectic soldering technology are prominent. The company has accumulated 10 years of eutectic technology precipitation, with reflow eutectic void rates controlled within 10%, significantly lower than similar products in the market. It has formed a relatively leading and complete set of process technologies for reducing void rates. Currently, the overall void area of its UVC LED products is below 10%, and the maximum void area per chip is below 2%, compared to the void rates of similar products in the market of 15%-30%, resulting in excellent heat dissipation, longer product lifespans, and better product quality control.

Regarding reliability, while packaging form is a factor, the key lies in air tightness. In semi-inorganic packaging, the glass lens and ceramic cup substrate form a sealed cavity through adhesive bonding. As vacuuming the closed cavity is not feasible, when the adhesive cures, the air inside the cavity is prone to thermal expansion, resulting in overflow and bubble formation, and in severe cases, the formation of air channels. At this point, external moisture and impurities can enter the product through bubbles and air channels, contaminating materials such as chips and substrates, seriously affecting product air tightness and, subsequently, light output and reliability

Shenzhen Yingfeng Opto-Electronic Co., Ltd.

Shenzhen Yingfeng Opto-Electronic Co., Ltd.