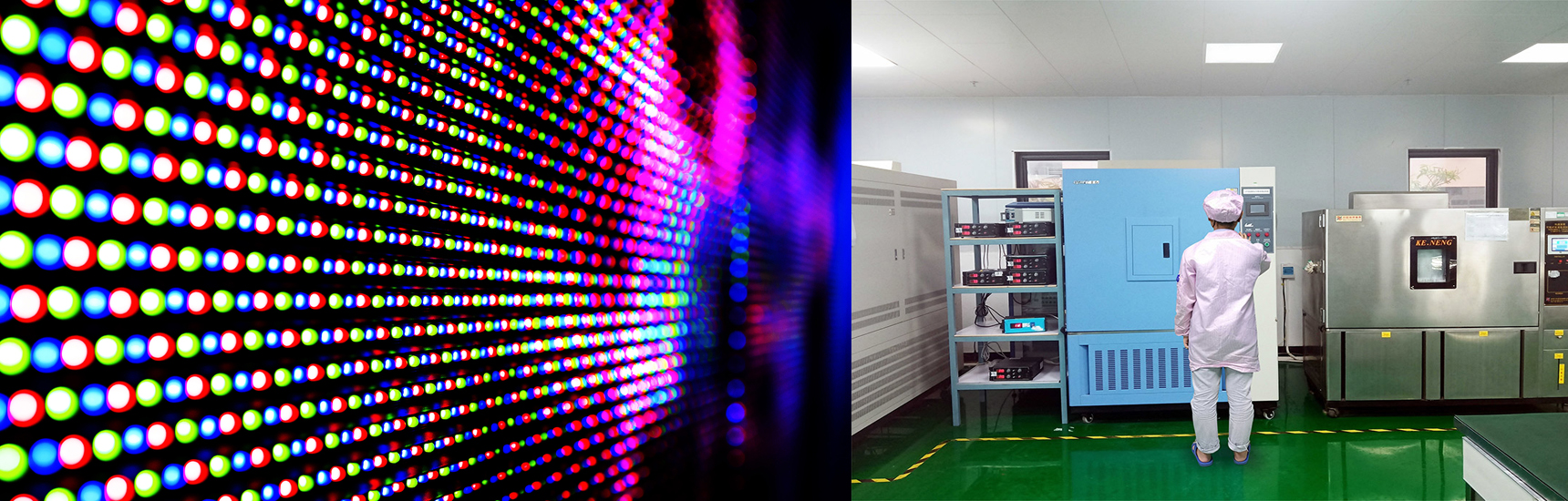

Yingfengphotoelectric R & D laboratory was completed in 2009, mainly for the reliability of LED packaging products testing and research and development, laboratory equipped with gold wire tension testing machine, plasma cleaning machine, programmable constant temperature and humidity chamber, thermal shock Test chamber, stent fracture testing machine. The improvement of the reliability of our LED products depends on the R & D personnel’s testing and analysis research and the operation of the laboratory

Bosen source pull machine

Push pull meter, is a kind of mechanical measuring instrument for thrust and tensile testing. Test the eutectic effect, the bonding strength of different materials, the welding effect, silver plastic sintering bonding force, the cohesion of solder paste eutectic, gold wire and chip PAD (electrode) eutectic bonding force: measuring the welding strength of gold wire

Thermal shock chamber

Used to test the structure of materials or composite materials in a very short period of time under extremely high temperature and low temperature enduring the extent of the environment in the shortest possible time to detect the specimen due to thermal expansion and contraction caused by chemical changes or physical damage.

Programmable constant temperature and humidity chamber

Used to test and determine electrical and electronic products and materials for high temperature, low temperature, alternating humidity or constant temperature changes in the environment after the test parameters and performance. Finished lit test to test the reliability of products under high temperature and humidity conditions.

Wei Bang fracture test machine

Test SMD stent mechanical strength.

Plasma cleaning machine

Plasma is an existing state of matter, in the vacuum chamber, through RF power under certain pressure to create a high-intensity disorderly plasma plasma generated by the bombardment of the surface to be cleaned to achieve the purpose of cleaning . Cleaning objects after plasma cleaning is dry, do not need to be dried and then sent to the next process. Plasma cleaning allows users to stay away from harmful solvents on the human body, but also to avoid wet cleaning easy to wash the problem of cleaning objects.

Plasma generated by high frequencies in the radio wave range is different from direct rays such as lasers. The poor directivity of the plasma makes it possible to drill into the tiny holes and recesses of the object to complete the cleaning task, so that it is not necessary to consider too much the shape of the object to be cleaned. Plasma cleaning can be treated regardless of object. Cleaning incoming bracket, solid crystal cleaning increases the reliability of the wire, plastic glue and scaffold before cleaning to increase the bond strength, the entire production process are used, after cleaning can increase the bond strength and shear strength.

Shenzhen Yingfeng Opto-Electronic Co., Ltd.

Shenzhen Yingfeng Opto-Electronic Co., Ltd.