Expunerea pe termen lung a automobilelor la medii în aer liber duce la îmbătrânirea accelerată a acoperirilor exterioare, Piele interioară, și componente ale sistemelor cu trei electrice datorită efectelor cuplate ale luminii naturale și ale temperaturii și umidității, care afectează în mod direct aspectul durabilității și siguranța funcțională a vehiculului. Prin replicarea precisă a spectrului solar, simulatoarele solare pot scurta ciclul de testare a îmbătrânirii la câteva luni sau chiar zile, făcându-l o tehnologie de bază în cercetarea materialelor auto și controlul calității. Acest articol al lui Zicrean Measurement and Control Yingfeng va analiza în mod sistematic principiile, standardele internaționale ale industriei, și scenarii tipice de aplicare a simulatoarelor solare în testele de îmbătrânire a automobilelor. Impactul luminii naturale asupra materialelor auto Yingfeng Procesul de îmbătrânire al materialelor auto sub lumină naturală depinde de natura luminii, intensitatea radiației, și proprietățile materialelor. Radiația soarelui, prin efectele sinergice ale unor factori precum iluminarea radiației, temperatura mediului ambiant, si umiditate, declanșează degradarea foto-oxidativă și îmbătrânirea termică pe suprafața materialului, conducând la degradarea performanței componentelor structurale auto și la o scădere a stabilității ansamblului. Caracteristicile multi-bandă ale spectrului radiației solare determină mecanismul complex de interacțiune al acestuia cu materialele auto, printre care ultraviolete (UV) radiatii, radiatii termice, iar radiația luminii vizibile sunt principalii factori de influență.

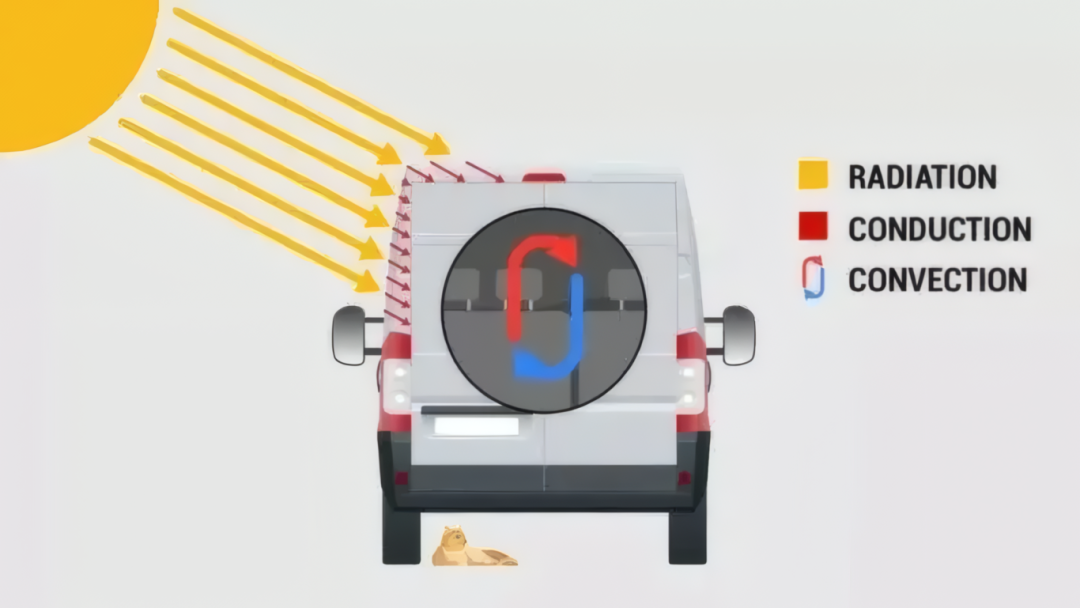

Raze ultraviolete (10 – 400 nm) provoca deteriorarea materialului prin deteriorarea lanțurilor moleculare polimerice: UV-A (400 – 320 nm) duce la degradarea unor materiale specifice cu molecul mare, UV-B (320 – 280 nm) are un puternic efect de degradare asupra majorității polimerilor, în timp ce UV-C (280 – 200 nm) are un impact slab asupra mediului natural datorita absorbtiei atmosferice. ■ Radiația termică afectează materialele prin absorbția și acumularea energiei termice ale acestora. În condiții de temperatură ridicată, este predispus să provoace fisurarea prin stres termic și stabilitatea dimensională redusă a materialelor plastice, cauciuc, etc., accelerarea ruperii lanțurilor polimerice și a reacțiilor de oxidare. ■ Radiația luminii vizibile acționează în principal asupra componentelor prin mecanismul de conversie a energiei termice. Gradul său de influență este strâns legat de intensitatea luminii, conductivitatea termică a materialului, și metode de tratare a suprafeței, și în cele din urmă exacerbează procesul de îmbătrânire al materialelor prin efectul de acumulare termică.

Principiul testării îmbătrânirii auto cu ajutorul unui simulator solar

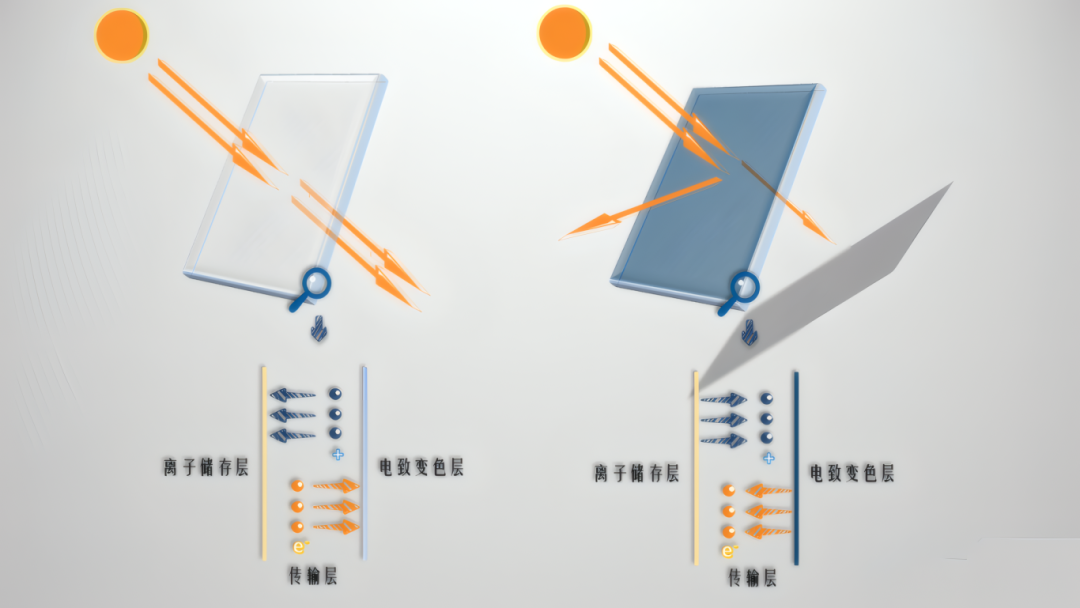

Simulatorul de lumină solară reproduce cu precizie spectrul solar (în special banda ultravioletă), combinat cu controlul temperaturii și umidității și sistem de pulverizare, pentru a simula procesul de îmbătrânire al materialelor auto atunci când sunt expuse la exterior pentru o lungă perioadă de timp. Mecanismele sale de bază includ: Reacție fotochimică: Lumină ultravioletă (290-400nm) determină ruperea sau reticulare a lanțurilor moleculare ale materialelor, rezultând modificări de culoare și degradarea proprietăților mecanice. Efect termic: Temperatura ridicată accelerează dilatarea termică și degradarea materialelor, cum ar fi fragilitatea plasticului și fisurarea acoperirii. Sinergia căldurii umede: Mediul cu umiditate ridicată favorizează reacțiile de hidroliză, intensificarea coroziunii metalice și umflarea materialelor cu molecul mare.

Simulator de lumină solară standard ISO: Yingfeng a condus

ISO 877: Metodă de expunere directă a materialelor plastice la radiația solară concentrată Fresnel și testul de expunere solară.

ISO 16750-4: Rata de distorsiune a imaginii a camerelor montate pe vehicul după îmbătrânirea termică umedă ≤ 0.3%. Simulator de lumină solară standard ASTM:Yingfeng ASTM G 90: Îmbătrânire accelerată în aer liber folosind lumina solară naturală concentrată. ASTM E 903: Măsurarea absorbției luminii solare și a ratelor de reflexie ale materialelor folosind o sferă integratoare.

Structura moleculară a materialelor auto se modifică sub acțiunea luminii ultraviolete

1. Materiale exterioare: Pentru barele de protecție și acoperirile vehiculelor, retenția și aderența culorii au fost evaluate prin teste de îmbătrânire cu lămpi cu xenon, și trebuiau să îndeplinească ΔE ≤ 2.0 (ISO 105-B02). Pentru sticla si capacele farurilor, atenuarea transmisiei luminii și indicele de îngălbenire (DO) au fost testate după iradiere cu ultraviolete. 2. Componente interioare: Pentru pielea scaunului, schema de control al luminii AI a scurtat perioada de testare de la 45 zile pentru a 72 ore, iar efectul de îmbătrânire a corelat expunerea naturală cu o rată de coincidență de peste 92%. Pentru plasticul tabloului de bord, combinația dintre ciclul de temperatură și umiditate (-40°C până la 80°C) iar testele de vibrații au fost folosite pentru a verifica rezistența la oboseală a materialului. 3. Sistem de propulsie nou energetic: Pachet de baterii: Socul variației temperaturii de la -40°C la 150°C + umiditate 95% Testul combinat RH a asigurat nivelul de protecție IP69K. Modul electronic de control: După îmbătrânire la căldură umedă la 85°C/85% RH, trebuia să treacă ISO 26262 certificare de siguranță funcțională. Tehnologia de testare a îmbătrânirii auto a simulatorului solar simulează mediul natural pentru a accelera deteriorarea materialului, furnizarea de metode științifice și eficiente de verificare a calității pentru producătorii de automobile. Cu progresele în sursele de lumină LED, algoritmi AI, și tehnologii de cuplare multifactorială, acuratețea și eficiența testului s-au îmbunătățit semnificativ, în timp ce costurile și consumul de energie au fost reduse semnificativ. În viitor, tehnologia simulatorului solar se va dezvolta în continuare către digitalizare și inteligență, sprijinind în continuare inovarea materialelor și îmbunătățirea fiabilității în domeniul auto.

LED-ul învolburat 1000-1750nm

LED-ul învolburat 1000-1750nm